What are the common mistakes in managing contractor safety? How to avoid them to keep your site safe, productive and profitable?

Robust contractor safety management programs protect the safety

and health of your team, your contractors, their subcontractors, and your reputation.

What are the key pillars for contractor

safety management?

What are the key pillars for contractor safety management?

Good contract management is the process that ensures both parties in a contract fully meet their respective obligations as efficiently and effectively as possible, in order to continually • deliver both the business and operational objectives required by the contract.

all parties know their obligations under the contract

the arrangements for service delivery continue to be satisfactory to both customer and supplier

expected business benefits and value for money are being delivered and realised, including safety and health performance

the supplier is co-operative and responsive

disputes are rare

the contract is fully compliant and satisfies both legislative and audit requirements.

Are contractors the weak link in your safety chain? If you don’t have an effective contractor safety management program, you may not even know. Here are some indicators to identify the weakness in contractor safety management.

Mistake 1

Neglecting Safety Performance Measures

Neglecting Safety Performance Measures

Reviewing the performance mechanisms and indicators that the company already had in place.

Mistake 2

Ignoring Proper Equipment Management

Construction equipment is the most vital capital asset contractors have. So, ignoring or being lax about proper managing equipment can lead to devastating results.

Mistake 3

Ignoring Change Management

Ignoring Change Management

As everyone strives to do more with less, adopting new technologies across the board ensures that one area of the company doesn’t reject new technology while others embrace it.

Mistake 4

Hiring or Assigning the Wrong Workers

It takes valuable time away from ensuring that the right workers are always being hired and assigned to the right jobs.

Mistake 5

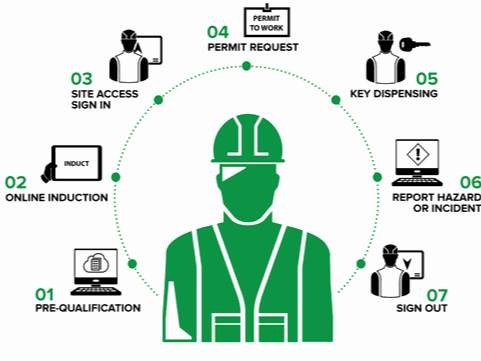

Outsourcing or rushing through Contractor Orientation Sessions

Outsourcing or rushing through Contractor Orientation Sessions

Not only can outsourcing also be a difficult logistical arrangement, but there is often no way of vetting whether contractors have actually understood the safety material.

Certainly, each of these mistakes require careful consideration on how they can best be implemented in your organisation. It is the ‘acting upon’ that is crucial to the improvement in CSM performance.

Measuring alone will not drive this improvement. The information the KPIs provide must be used by senior managers to change CSM policy, procedures, practices and beliefs, and it is these changes that will drive CSM improvement, one word “Leadership”.

| Views | |

|---|---|

| 1260 | Total Views |

| 1 | Members Views |

| 1259 | Public Views |

| Actions | |

|---|---|

| 0 | Likes |

| 0 | Dislikes |

| 0 | Comments |

Share by mail

Please login to share this webpage by email.